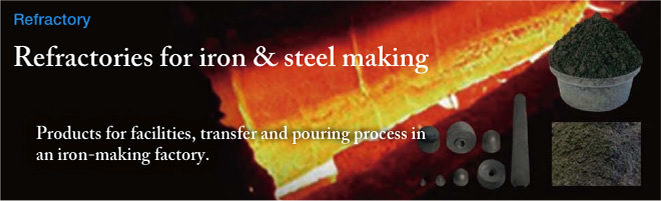

Repairing Material

Various materials are available for the repair of a furnace inner lining, runner, tap hole, and ladle of a

blast furnace. They can exhibit a stable workability and durability throughout the room to hot temperature

condition. Those are used as easy repair materials.

Properties |

| Material | Alumina・Silicon Carbide・Graphite Quality | |

|---|---|---|

| Chemical Composition (%) |

F.C. | 2 to 7 |

| SiO2 | 3 to 10 | |

| Al2O3 | 55 to 75 | |

| SiC | 20 to 40 | |

Properties Sintered at 1400℃ |

Compression Strength (MPa) | 20 to 70 |

| Modulus of Rupture(MPa) | 2 to 10 | |

| Installation Quantity(Kg/m3) | 2100 to 2800 | |

The “HOTTCAST” series are new repair materials developed for the repair in the hot atmosphere. They

are superior repair materials that have easy installation, short repair, high erosion resistance, and high

adhesiveness. Those can be achieved by the self work process of softening, flowing, filling, hardening,

and carbonizing.

Properties |

| Product Name | HOTTCAST | |

|---|---|---|

| Material | Alumina・Silicon Carbide・Carbon Quality | |

| Chemical Composition (%) |

F.C. | 6 |

| SiC | 15 | |

| Sio2 | 2 | |

| Al2O3 | 72 |

|

| Properties Sintered at 1450℃ |

Compression Strength(MPa) | 18.0 |

| Modulus of Rupture(MPa) | 3.0 | |