With our own technology skills developed since our foundation

in the Meiji-era,

we will improve the stability and durability of our products.

“Phoenix” Series

Carbon Bonded Silicon Carbide Graphite Crucible

- Reliable technology accumulated by research and development

over a century. - Various product lines to meet various applications.

- Different shapes and sizes available to meet

customer needs and requirements.

|

Nippon Crucible has gained great popularity with its original technology accumulated over a century since its foundation in year 1985 as the first graphite crucible manufacturer in Japan, and made good reputation by satisfying a wide variety of customer needs today. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

■Characteristics:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

■Various Shapes:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

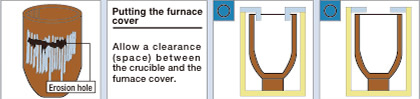

■Precautions for crucible use: |

|

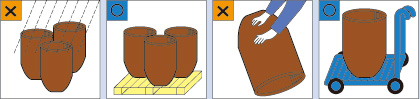

| 1. Be careful when storing and transporting a crucible. |

|

|---|---|

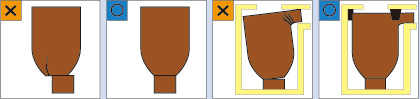

| 2. Select a crucible stand that meets the bottom diameter of a crucible and place it in the correct position. |

|

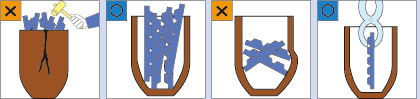

| 3. Charge ingots carefully so as not to over-stuff the crucible. |

|

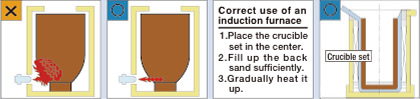

| 4. Do not expose the crucible to the burner's flame. |

|

| 5. Minimize the use of flux as much as possible. |

|

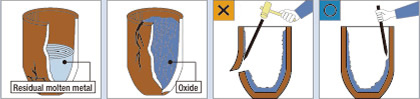

| 6. Pay attention to the crucible while working. Attachment of remaining molten metal and oxides will cause a crucible to break. |

|