TOP>

Products>

Refractory>

Refractories for cast iron and cast steel>

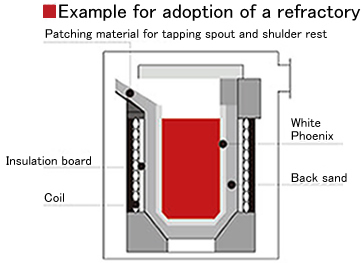

Crucible for High Frequency Induction Furnace “White Phoenix”

Our products meet the needs of various types of

metals and its melting methods.

Crucible for High Frequency

Induction Furnace “White Phoenix”

- Selectable materials and production

methods depending on metal melting/use

conditions/cost efficiency.

- CIP(Cold Isostatic Pressing) forming,

injection

forming, friction press forming,

and

stamp forming.

■Properties

| Forming method |

CIP |

| Material |

MU |

A |

AS5 |

MS |

M |

Aluminum/

Mullite |

Aluminum |

Aluminum/

Spinel |

Magnesium/

Spinel |

Magnesium |

Chemical

Compositions

(%) |

Al2O3 |

93 |

99 |

84 |

61 |

28 |

| SiO2 |

6 |

- |

- |

- |

- |

| MgO |

- |

- |

15 |

38 |

70 |

| Bulk Gravity |

2.80 |

3.00 |

2.90 |

2.90 |

2.90 |

Apparent

Porosity(%) |

23 |

23 |

23 |

22 |

21 |

Compression

stregth(MPa) |

44 |

36 |

44 |

34 |

33 |

Heatl expansion

rate (%) |

at1000 |

0.65 |

0.80 |

0.80 |

0.90 |

1.00 |

| Heat

conductivity (W/mk) |

at R.T. |

2.3 |

5.2 |

4.4 |

3.9 |

3.5 |

| Princupal use |

Special steel/

Castiron/

cast steel

|

Special

/Castiron

/Cast steel |

Spesial steel/

stainless steel |

Spesial steel/

stainless steel |

Spesial steel/

stainless steel |

※These figures are typical values and not guaranteed

|

| Forming method |

Precast |

Stamp |

| Material |

CASTIX

-620 |

SIXTEX

-90R |

AF96 |

S2 |

Alumina/

Silicon Carbide

(SiC) |

SiC |

Aluminum |

Sillica |

Chemical

Compositions

(%) |

Al2O3 |

57 |

4 |

96 |

- |

| SiO2 |

30 |

3 |

4 |

98 |

| MgO |

SiC10 |

SiC90 |

- |

- |

| Bulk Gravity |

2.66 |

2.58 |

3.23 |

1.90 |

Apparent

Porosity(%) |

- |

19 |

14 |

- |

Compression

stregth(MPa) |

170 |

69 |

122 |

19 |

Heatl expansion

rate (%) |

at1000 |

- |

- |

- |

- |

| Heat

conductivity (W/mk) |

at R.T. |

- |

9.3

(at1,000℃) |

- |

- |

| Princupal use |

Special steel/

Aluminum |

Aluminum |

Special steel |

Cast iron |

※These figures are typical values and not guaranteed

|

|

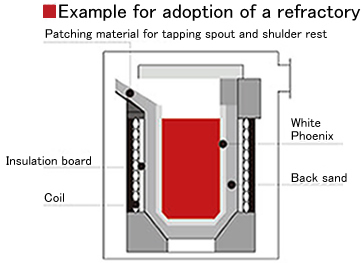

■Back sand |

| Material |

EDR-BS4 |

EDR-BS10 |

EDR-BS970 |

Chemical

composition

(%) |

Al2O3 |

40 |

99 |

97 |

| SiO2 |

55 |

- |

(Ti02)2 |

Installation

quantity(Kg/㎥) |

1,750 |

2,750 |

3,100 |

|